PVC Pipe and Profile Designed for Extruders Conical Twin Screw Barrel – Efficient Production, Wear Resistant, Factory Direct Sale

PVC Pipe Production: Suitable for manufacturing various specifications of water supply pipes, drainage pipes, and corrugated pipes.

PVC Profile and Sheet Production: The production of PVC profiles, which can be used in building decorative materials such as doors and windows, wall panels, ceiling panels, and stair railings.

Other plastic products: In addition, PVC floors, faux marble boards, and other plastic products can be manufactured.

Manufacturing experience

Deep background: The company has over 27 years of mechanical manufacturing experience, witnessing the development and transformation of Chinese manufacturing.

Rich case library: Successful cases can be found in over 100 countries around the world.

Production equipment

Advanced equipment: By introducing international advanced CNC processing centers, automated assembly lines, and other high-end equipment, we have realized a 30% increase in production efficiency.

Smart manufacturing: By adopting industrial internet technology and implementing the ERP system, real-time monitoring and data analysis of the production process are achieved, resulting in a 90% improvement in production accuracy.

Quality control capability

Strict quality control: A comprehensive quality management system is established, from raw material entry to finished product output, every step is rigorously tested, and the reject rate is controlled below 5 permil.

Continuous improvement: Constantly optimize the production process to enhance the stability of product quality, achieving a customer satisfaction rate of 100%.

Product quality certification

Authoritative certification: The product has been certified by the ISO 9001 quality management system.

Industry benchmark: Awarded the title of "Zhejiang High-tech Enterprise," and multiple products are rated as "Zhejiang Famous Products."

Uniform mixing: The conical twin-screw design ensures that the material is well mixed during the extrusion process, resulting in the uniformity of the product.

High output: Efficient extrusion speeds and large capacity design significantly increase production efficiency.

Versatile application: Suitable for the production of various plastic products, such as pipe, profile, and sheet.

Wear-resistant materials: The screws and barrel are manufactured from high-quality alloy steel or special wear-resistant materials to ensure stable operation over a period of time.

Anti-corrosion coating: Parts that come into contact with corrosive materials are treated with a special anti-corrosion coating to extend the lifespan of the equipment.

Double-screw coordination: The two screws intermesh, driving the material forward through rotation while performing cutting, compressing, and blending.

Temperature control: A precise temperature control system ensures that the material melts at its best state, avoiding excessive heat that may lead to decomposition.

Self-cleaning capability: The self-cleaning action between the screws reduces the accumulation of residual materials, making it easier and faster to clean.

Flexible adjustment: The speed and temperature of the screws can be adjusted based on different materials and product requirements.

Energy conservation and environmental protection: Energy consumption is reduced by 30% compared to traditional single-screw extruders, lowering production costs.

Operational simplicity: A fully automated control system streamlines the process and reduces human intervention.

Stable and reliable: The structure is well-designed, which reduces the failure rate and enhances the stability and reliability of the equipment.

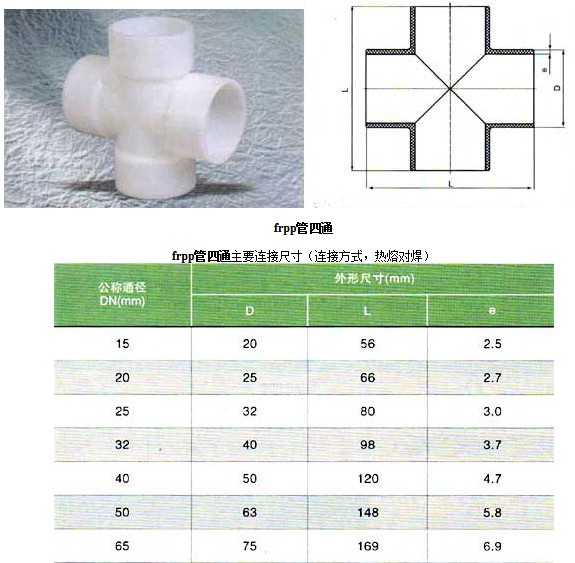

The technological parameters of the conical twin-screw extruder will vary depending on the model, such as:

| 型 | |||||||

| 45/90 | 45/100 | 51/105 | 55/110 | 58/124 | 60/125 | 65/120 | 65/132 |

| 68/143 | 75/150 | 80/143 | 80/156 | 80/172 | 92/188 | 105/216 | 110/220 |

1.淬火回火后硬度:HB280-320。

The hardness after quenching and tempering:HB280-320。

2.氮化硬度:HV920-1000。

Nitrded Hardness:HV920-1000。

3.氮化層深度:0.50-0.80mm。

Nitrided Case Depth:0.50-0.80mm。

4.氮化脆性:小于2級。

Nitrided Brittleness:Less Than Grade 2。

5.表面粗糙度:Ra 0.4。

Surface Roughness:Ra 0.4。

6.螺桿直線度:0.015mm。

Screw Straightness:0.015mm。

7.氮化后表面鍍鉻層硬度:≥900HV。

Surface Chromium-Plating's Hardness After Nitriding:≥900HV。

8.鍍鉻層厚度:0.025-0.10mm。

Chromium-plating Depth:0.025-0.10mm。

9.雙合金硬度:HRC55-65。

Alloy Hardness:HRC55-65。

10.合金深度:2.0-3.0毫米。

Alloy Depth:2.0-3.0mm

When selecting a conical twin-screw machine, you should consider your specific needs, including the required output, type of material, product specifications, and budget. At the same time, also take into consideration the reputation and service quality of the supplier, as well as the convenience of maintenance and operation. If possible, it's best to visit the manufacturer's factory and personally assess the performance and quality of the machines.

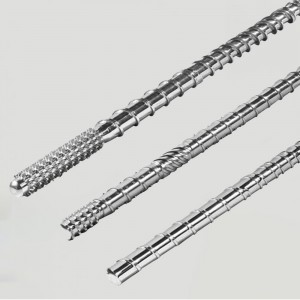

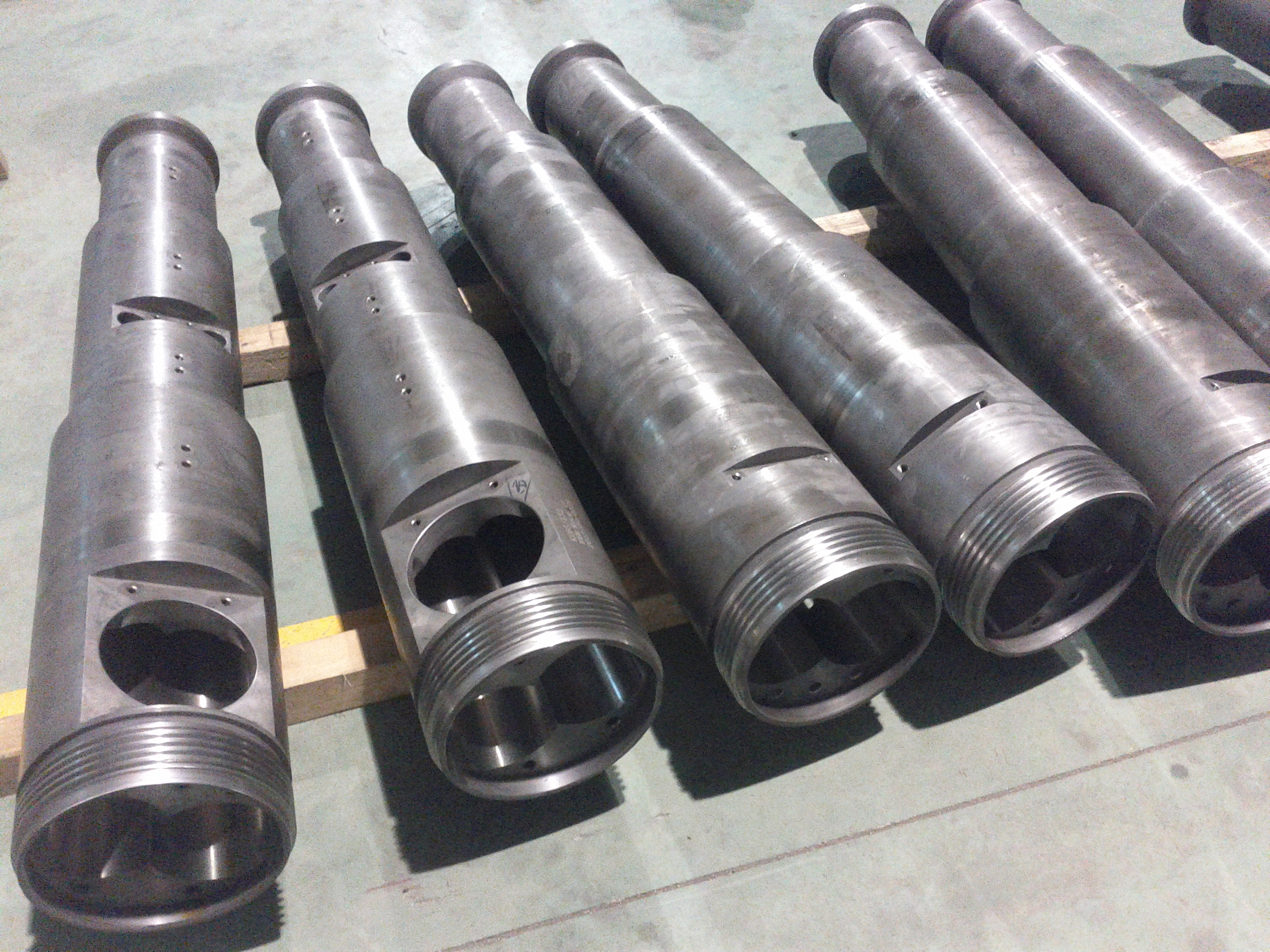

? ? FINISHED PRODUCTS PICTURES OF SCREW BARREL

Showcase high-definition images of key components such as the screw rod, cylinder, and transmission system.

Show the actual application situation of the conical twin-screw extruder in different production environments.

Application scenario: The conical twin-screw extruder is particularly suitable for the direct forming of PVC powder, and if the geometric structure of the screws is changed, it can also be used for the forming of other materials.

High-resolution images of key components such as display screws, cylinders, and drive systems.

1、Company Service Process

Requirement Analysis Phase: Jinteng Machinery's professional sales team will engage in in-depth communication with clients to thoroughly understand their production needs and desired objectives, followed by a detailed analysis of these requirements.

Design Proposal: Based on the outcomes of the needs analysis, the engineering team will develop a customized conical twin-screw extruder design proposal, encompassing specifications and performance parameters.

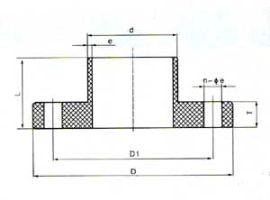

Customer Confirmation: Present the connection dimension drawings to the client to obtain their feedback and confirmation.

batch production translation:After obtaining customer approval, initiate the mass production process to ensure product quality and delivery deadlines.

2、customer service team

Sales Design Proposal: Based on the outcomes of the needs analysis, the engineering team will develop a customized conical twin-screw extruder design proposal, encompassing specifications and performance parameters.

Design and Development Team:The team comprises seasoned senior engineers who possess innovative design concepts and robust technical capabilities.

Production Manufacturing Team:Adhere to the ISO quality management system standards to ensure the precision and quality of each set of products.

Customer Support Team:Quickly respond to customer needs and provide timely and effective technical support and maintenance services.

3、Packaging and Shipping Services

Custom Packaging:Based on the characteristics of the conical twin-screw extruder, design a special anti-vibration packaging solution to ensure the safety of the product during transportation.

Logistics Distribution:Choose a reliable logistics partner to provide the corresponding transport service, ensuring that the equipment arrives at the customer's specified location on time.

Export service: For overseas customers, Jinteng Mechanical still provides export-related document preparation and customs clearance services.