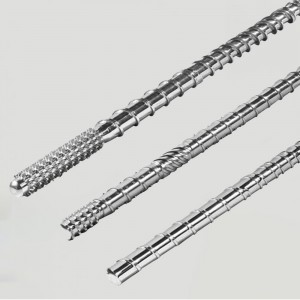

Single screw barrel for recycling granulation

Pelletizing extruders can be used to process a wide variety of different plastics, each with its own unique properties and areas of application. Here are some common plastic types and their applications.

Polyethylene (PE): Polyethylene is a common plastic with good toughness and corrosion resistance. It is widely used in plastic bags, plastic bottles, water pipes, wire insulation materials and other fields.

Polypropylene (PP): Polypropylene has excellent high-temperature stability and mechanical properties, and is often used in the manufacture of plastic products such as food packaging, medical devices, and household items.

Polyvinyl Chloride (PVC): PVC is a versatile plastic that can be made into soft or hard materials according to different formulations. It is widely used in the manufacture of building materials, wires and cables, water pipes, floors, vehicle interiors, etc.

Polystyrene (PS): Polystyrene is a hard and brittle plastic commonly used in the manufacture of food containers, electrical housings, household items, and more.

Polyethylene Terephthalate (PET): PET is a clear, strong and heat-resistant plastic that is commonly used to make plastic bottles, fibers, films, food packaging, and more.

Polycarbonate (PC): Polycarbonate has excellent impact resistance and transparency, and is widely used in the manufacture of mobile phone cases, glasses, safety helmets and other products.

Polyamide (PA): PA is a high-performance engineering plastic with excellent heat resistance, wear resistance and strength. It is often used in the manufacture of automotive parts, engineering structural parts, etc.

The above are just a few common types of plastics and their applications. There are actually many other types of plastics, all of which have their own unique characteristics and a wide range of applications. The pelletizing extruder can be adjusted and adapted according to the characteristics of different plastics to meet the needs of different customers.