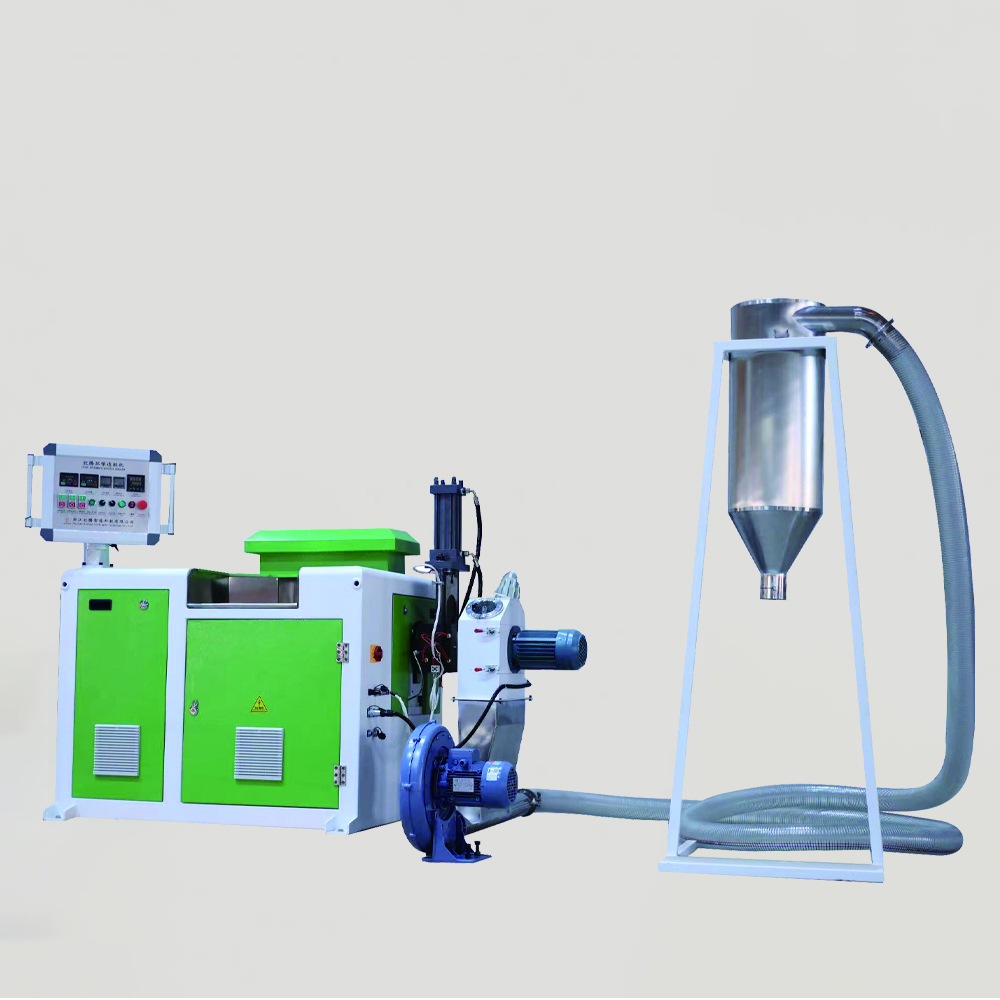

Single Screw Extruder

The product classification of single screw extruder can be described through the following three terms:?vented single screw extruder, single screw machine, and waterless granulator machine.

Vented single screw extruder: This product category refers to single screw extruders equipped with a venting system, allowing the release of volatiles and gases from the material being processed. Vented extruders are commonly used for applications involving moisture-sensitive materials, reactive processing, and the removal of volatile components during the extrusion process. The venting capability enhances the quality and properties of the extruded products, making vented single screw extruders suitable for a wide range of applications, including polymer devolatilization, reactive extrusion, and the production of high-quality compounds.

Single screw machine: The single screw machine category encompasses a broad range of single screw extruders designed for various applications in the plastics, rubber, food, and pharmaceutical industries. These machines are engineered to provide efficient melting, mixing, and shaping of the materials, catering to diverse processing requirements. Single screw machines are available in different configurations, including short L/D (length to diameter) ratios for melting and mixing, long L/D ratios for devolatilization, and specialized designs for specific materials and processes.

Waterless granulator machine: This category includes single screw extruders specifically designed for waterless granulation processes. These extruders are equipped with advanced technology to efficiently convert plastic materials into granules without the use of water. Waterless granulator machines are suitable for processing a wide range of plastic resins, offering advantages such as energy efficiency, reduced environmental impact, and improved product quality.