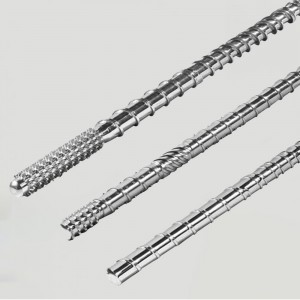

Twin screw extruder

JTZS series conical twin-screw plastic extruder, has forced extrusion,high quality, wide adaptability,long service life, small shear rate, material is difficult to decompose, good mixing plasticizing performance, direct powder-molding and so in the characteristics equipped with DC speed regulation, Automatic temperature, vacuum exhaust device. Twin-screw extruder is a type of equipment used in processing plastics, rubber, food, pharmaceutical and chemical industries. They are commonly used in plastic production, such as the production of plastic pipes, sheets, films, granules, etc. Twin-screw extruders are also widely used in the food processing industry to make various foods, such as noodles, puffed foods and candies. In the pharmaceutical and chemical industries, twin-screw extruders can also be used to produce pharmaceuticals, cosmetics and chemical products.

1.The soft plastic design concept,ensures the quality of material.

2.Very reliable and effective design theory,ensures the extrusion operation.High torque special drive system,gear,shaft for high strength alloy steel,carburizing,abrasion resistance treatment.

3.The new development of the screw,suitable for formulation of the high amount of filler,guarantee the material in screw good filling degree and the best distribution of material flow.

4.Screw with core temperature reguating device and a well barrel cooling,ensure the accurate control of the temperature of material process.

5.Match different dies and materials for extrusion molding all kinds of pipe,profile and soft(hard)PVC granulation.

| Project/model | JTZS 51 | JTZS 65 | JTzS 80 | JTzS 92 |

| Screw diameter (mm) | 51/105 | 65/132 | 80/156 | 92/188 |

| Screw quantity | 2 | 2 | 2 | 2 |

| Screw turning | Different to outside counter-rolation | outward | ||

| Screw rotational speed (rpm) | 2-32 | 1-32 | 1-32 | 1-32 |

| Screw effective length (mm) | 1070 | 1441 | 1800 | 2500 |

| Structural style | Cone meshing | |||

| Main electrical machinery power (kW) | 22 | 37 | 55 | 90 |

| Total power (kW) | 40 | 67 | 90 | 120 |

| Max.extrusion | 120 | 300 | 400 | 800 |

| Barre heating segment number | 4 | 4 | 4 | 5 |

| Heating methods | Screw quantitative | |||

| Screw center height (mm) | 1000 | 1000 | 1000 | 1000 |

| Weight (kg) | 3200 | 4000 | 5000 | 7000 |

| Dimensions (mm) | 3000x1050×2200 | 4230x1520×2450 | 4750×1550×2460 | 6700x1560×2820 |